Niobium, an underrated element, has been used for decades in various industries, ranging from aerospace to medical and automotive applications. It is a chemical element and a transition metal with the symbol Nb and atomic number 41.

Niobium is a versatile element that is well-known for its corrosion resistance, magnetic properties, strength, and cost-efficiency.

Introduction

The first notable use of niobium was in 1801 when Charles Hatchett discovered it. He named the element columbium, but it was later renamed niobium in 1949 as the name columbium had already been used for another element.

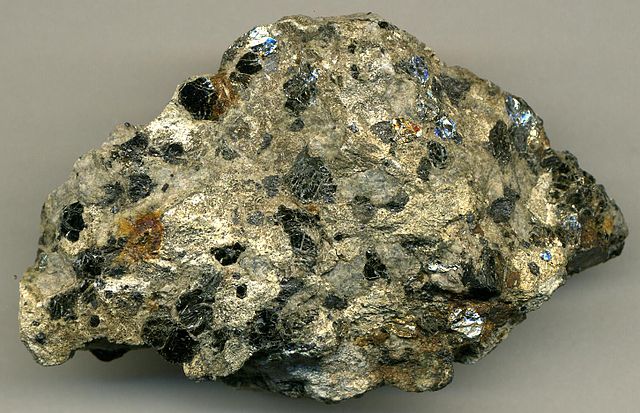

Niobium is a silvery-grey metal that is soft, ductile, and malleable. It can be found in nature combined with other elements such as tantalum, zirconium, and thorium. It is also found in many ores, including niobite or columbite.

Niobium has an atomic number of 41 and atomic weight of 92.906. It has an oxidation state of +3 or +5 and a melting point of 2477°C.

The physical properties of niobium make it very attractive for a variety of applications. Its lightweight and high strength make it ideal for aerospace and automotive applications. It is also highly resistant to corrosion, making it well-suited for chemical and medical industries. Furthermore, it has low thermal neutron capture cross-sections, making it a suitable material for nuclear reactors and power plants.

Niobium has a variety of applications, making it an extremely useful element. It is used in the aerospace industry for rocket and airplane parts, as it is lightweight yet strong. It is also used in medical fields for surgical implants and prosthetics, due to its corrosion-resistant properties. Other applications for niobium include automotive parts, electronics, and steel production.

Niobium is also used in the form of superconductors, which are materials that can conduct electricity without any resistance. This makes them extremely energy-efficient and is the primary reason why niobium is used in this form.

It is also used in combination with other metals to produce alloys that are highly resistant to corrosion and have magnetic properties.

In conclusion, niobium is an underrated chemical element that has a wide range of uses and benefits. It has many physical properties that make it attractive for a variety of applications, such as aerospace, medical, and automotive uses. It is also used in forming alloys and superconductors that have corrosion-resistant and magnetic properties. Its strength and durability make it cost-effective and non-toxic, making it an optimal material for many industries.

Chemical Properties

Niobium is a chemical element with an atomic number of 41 and an atomic weight of 92.90638. It is located on the periodic table in the 5th group in the 5th period. It is a shiny, white-colored metal that is soft and ductile.

This element is best known for its corrosion resistance, magnetic properties, and its ability to be used as a superconductor.

The most common oxidation states of niobium are +2, +3 and +4. The melting point for niobium is 2477°C or 4491°F. The boiling point is 4744°C or 8571°F. At room temperature, niobium is brittle and fragile.

When heated, niobium is transformed into a ductile and malleable metal. It can also be alloyed with other metals such as iron, cobalt, nickel, and titanium. This allows niobium to be used in a variety of applications.

Niobium has an electronegativity that is comparable to iron, tin, and titanium. It also has a high thermal conductivity, electrical conductivity, and a low thermal expansion rate. Niobium also has a high tensile strength, making it an ideal material for use in aerospace applications.

Niobium is often used in alloys to increase strength and resistance to corrosion. It is also used in medical implants due to its non-toxic nature. It is commonly used in the automotive industry for lightweight components. Niobium is also used in electronics to increase the efficiency and performance of components such as transistors.

Niobium is a versatile chemical element that has a variety of uses and benefits. Its corrosion resistance, magnetic properties, and ability to be used as a superconductor make it an ideal material for a variety of applications. Its light weight and strength make it ideal for aerospace use, while its non-toxic nature makes it safe for medical applications.

Niobium is also cost-effective and can be easily alloyed with other metals to increase its strength and durability.

Applications

Niobium has a number of industrial uses that have been gaining in popularity over the last few decades. It is a highly versatile metal which makes it ideal for a wide range of applications in different industries. Here, we will take a look at the different ways that niobium is used across various industries.

Aerospace: Niobium is used in the aerospace industry as an alloying element. It is used to create lightweight, high-strength alloys which can be used in aircraft engines and other components. It also provides heat resistance and corrosion resistance which makes it ideal for these types of applications.

Medical: Niobium is used in medical applications such as implants and prosthetics. It is highly biocompatible, which makes it a great choice for medical applications. It is also non-toxic and lightweight, which makes it safe to use in the body.

Automotive: Niobium is used in automotive applications due to its ability to provide corrosion and heat resistance. It is used to create strong, lightweight alloys which can be used in car engines and other components. It is also used to create parts that are resistant to wear and tear.

Electronics: Niobium is used in the electronics industry due to its magnetic properties. It can be used to create coils and other components which can be used in a variety of different electronic applications. It is also highly conductive and provides a great deal of heat resistance, which makes it ideal for use in electronic components.

Niobium has a number of uses across various industries, which makes it a highly versatile and versatile metal. Its ability to provide corrosion and heat resistance, as well as its magnetic properties, make it a great choice for a wide range of applications.

Forming Niobium

Niobium is a chemical element with the atomic symbol Nb, atomic number 41, and an atomic weight of 92.906. It’s a soft, grey-white metal and, like many other metals, is found in nature in its elemental form.

There are two ways to isolate and form niobium: extraction and refining.

Extraction

Niobium is found in the form of ores, which are typically processed through pyrometallurgical extraction. This means heating and reducing the ore to its elemental form.

During this process, several other elements are also isolated and removed from the niobium ore. These elements can include iron, titanium, tantalum, and zirconium.

The second step of the extraction process is to separate the individual elements from the ore concentrate. This is accomplished through the use of a variety of solvent extraction and electrowinning techniques.

The final result of this process is a cold-pressed powder containing pure niobium.

Refining

The next step in forming niobium is to refine the ore concentrate. This is done using a variety of electrolysis and chemical processes such as the Hall-Heroult Process. This process creates a molten solution of niobium and impurities.

The impurities are then removed through a variety of filtration and purification techniques.

The final step of the refining process is to cast the niobium into ingots or bars in order to be used for a variety of purposes. This process is usually done in a vacuum furnace to ensure the highest quality product.

Alloying

Another way of forming niobium is by alloying it with other metals. This is done by adding other metals such as tantalum, titanium, or stainless steel to niobium ore. This creates a new material with different characteristics and properties.

Such alloys are used in the production of a variety of products such as aerospace parts, medical implants, and automotive parts.

Alloying niobium is also a great way to increase its strength and durability. This is because the addition of other metals creates a much stronger and more durable material than pure niobium.

There are a variety of ways to form niobium, but the most efficient and cost-effective methods are extraction and refining. These processes can be used to create a pure, cold-pressed niobium powder or a strong and durable alloy that can be used in a variety of applications.

Uses of Niobium

Niobium is a versatile element, offering a variety of uses across industries. Its unique physical and chemical properties make it a valuable component for a range of applications.

One of its most useful features is its ability to function as a superconductor. This means it can effectively carry and control electrical currents without any resistance. This property makes it ideal for use in advanced electrical motors, generators, and other electrical equipment.

Niobium also exhibits excellent corrosion resistance, which means it stands up well to harsh environments. This makes it a popular choice for medical implants, as well as for use in industrial and chemical processes.

Niobium also has some useful magnetic properties. This means that it can be used to create magnets that can be used in a range of devices, from refrigerators to electric motors.

In steel production, niobium can be used to strengthen the steel, making it more durable and resistant to corrosion. This makes it an invaluable resource for the automotive and construction industries.

Niobium can also be used to form alloys, which can be used to create a range of products. These alloys are often used to create items such as pipes and tubes due to their strength and durability.

Finally, niobium is also a very lightweight element, making it ideal for use in aircraft and other aerospace applications. The lightness of niobium makes it a popular choice for creating items such as propellers and turbines.

Overall, niobium offers a wide range of uses across a variety of industries. Its unique properties make it an invaluable element in the modern world. It is cost-effective, non-toxic, and durable, making it an ideal choice for many applications.

Benefits of Niobium

When it comes to benefits, there is no denying that niobium offers many advantages that make it an attractive option for many industries. Here are some of the main benefits of using niobium in various applications.

Strength and Durability: Niobium is a highly dense material which makes it incredibly strong and durable. It is an especially good choice for applications that require materials to be resistant to corrosion, wear, and tear, or any other environmental effects. Due to its impressive strength, niobium is also used for applications such as missile guidance systems and military vehicles.

Cost-Effective: Due to its abundance, niobium is an extremely cost-effective material. It is much cheaper than other materials such as titanium, which makes it an attractive option for many industries that require strong and durable materials at a lower cost.

Non-Toxic: Niobium is a non-toxic material which makes it safe for use in medical applications and other applications that require contact with the human body. It is also an environmentally friendly material that has no adverse effects on the environment.

Lightweight: Another advantage of niobium is its low weight. It is much lighter than other materials, such as steel, which makes it an ideal choice for applications such as aircraft and spacecraft parts where weight is a major factor.

These are just some of the main benefits of niobium that make it an attractive choice for many industries, such as aerospace, medical, automotive, and electronics. Its low cost, strength, and durability make it a great choice for many applications. It is also a non-toxic material which makes it safe to use in applications that need contact with the human body.

Finally, its lightweight nature makes it a great choice for applications where weight is a major factor. All of these benefits make Niobium an attractive option for many different industries.

Facts

Niobium is a chemical element with chemical symbol Nb

It has the atomic number 41

The name niobium was adopted internationally in 1950.

In 1801, Charles Hatchett discovered a new element in a sample of the ore columbite, and named it columbium.

The element was originally called columbium (symbol Cb).

The names ‘columbium’ and ‘niobium’ were both used to identify the element until 1949

There is only one known stable isotope of niobium, Nb-93.

The element name comes from ‘Niobe’ meaning daughter of Tantalus in Greek mythology.

Niobium is a lustrous, grey, ductile, paramagnetic metal in group 5 of the periodic table

Niobium becomes a superconductor at cryogenic temperatures

The metal takes on a bluish tinge when exposed to air at room temperature for extended periods

Niobium is estimated to be the 34th-most common element in Earth’s crust, at 20 ppm

Minerals that contain niobium often also contain tantalum

By 2003, at least 32 radioisotopes had been synthesized, ranging in atomic mass from 81 to 113

The most stable is 92Nb with half-life 34.7 million years

The three largest currently mined deposits of pyrochlore, two in Brazil and one in Canada

Brazil produces about 88% of the world’s supply.

The leading producer of niobium outside of Brazil is the Niobec Mine in Quebec, Canada.

Out of 44,500 tonnes of niobium mined in 2006, an estimated 90% was used in high-grade structural steel.

Niobium is considered a technology-critical element.

One of the most common niobium alloys is ferroniobium, where it is combined with iron.

Niobium is used in jewelry making because of its low level of toxicity.

Information

| Niobium | |||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pronunciation | ny-OH-bee-əm | ||||||||||||||||||||||||||||||||||||||||

| Appearance | gray metallic, bluish when oxidized | ||||||||||||||||||||||||||||||||||||||||

| Standard atomic weight Ar°(Nb) | |||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

| Niobium in the periodic table | |||||||||||||||||||||||||||||||||||||||||

| Atomic number (Z) | 41 | ||||||||||||||||||||||||||||||||||||||||

| Group | group 5 | ||||||||||||||||||||||||||||||||||||||||

| Period | period 5 | ||||||||||||||||||||||||||||||||||||||||

| Block | d-block | ||||||||||||||||||||||||||||||||||||||||

| Electron configuration | [Kr] 4d4 5s1 | ||||||||||||||||||||||||||||||||||||||||

| Electrons per shell | 2, 8, 18, 12, 1 | ||||||||||||||||||||||||||||||||||||||||

| Physical properties | |||||||||||||||||||||||||||||||||||||||||

| Phase at STP | solid | ||||||||||||||||||||||||||||||||||||||||

| Melting point | 2750 K (2477 °C, 4491 °F) | ||||||||||||||||||||||||||||||||||||||||

| Boiling point | 5017 K (4744 °C, 8571 °F) | ||||||||||||||||||||||||||||||||||||||||

| Density (near r.t.) | 8.57 g/cm3 | ||||||||||||||||||||||||||||||||||||||||

| Heat of fusion | 30 kJ/mol | ||||||||||||||||||||||||||||||||||||||||

| Heat of vaporization | 689.9 kJ/mol | ||||||||||||||||||||||||||||||||||||||||

| Molar heat capacity | 24.60 J/(mol·K) | ||||||||||||||||||||||||||||||||||||||||

Vapor pressure

|

|||||||||||||||||||||||||||||||||||||||||

| Atomic properties | |||||||||||||||||||||||||||||||||||||||||

| Oxidation states | −3, −1, 0, +1, +2, +3, +4, +5 (a mildly acidic oxide) | ||||||||||||||||||||||||||||||||||||||||

| Electronegativity | Pauling scale: 1.6 | ||||||||||||||||||||||||||||||||||||||||

| Ionization energies |

|

||||||||||||||||||||||||||||||||||||||||

| Atomic radius | empirical: 146 pm | ||||||||||||||||||||||||||||||||||||||||

| Covalent radius | 164±6 pm | ||||||||||||||||||||||||||||||||||||||||

| Other properties | |||||||||||||||||||||||||||||||||||||||||

| Natural occurrence | primordial | ||||||||||||||||||||||||||||||||||||||||

| Crystal structure | body-centered cubic (bcc) | ||||||||||||||||||||||||||||||||||||||||

| Speed of sound thin rod | 3480 m/s (at 20 °C) | ||||||||||||||||||||||||||||||||||||||||

| Thermal expansion | 7.3 µm/(m⋅K) | ||||||||||||||||||||||||||||||||||||||||

| Thermal conductivity | 53.7 W/(m⋅K) | ||||||||||||||||||||||||||||||||||||||||

| Electrical resistivity | 152 nΩ⋅m (at 0 °C) | ||||||||||||||||||||||||||||||||||||||||

| Magnetic ordering | paramagnetic | ||||||||||||||||||||||||||||||||||||||||

| Young’s modulus | 105 GPa | ||||||||||||||||||||||||||||||||||||||||

| Shear modulus | 38 GPa | ||||||||||||||||||||||||||||||||||||||||

| Bulk modulus | 170 GPa | ||||||||||||||||||||||||||||||||||||||||

| Poisson ratio | 0.40 | ||||||||||||||||||||||||||||||||||||||||

| Mohs hardness | 6.0 | ||||||||||||||||||||||||||||||||||||||||

| Vickers hardness | 870–1320 MPa | ||||||||||||||||||||||||||||||||||||||||

| Brinell hardness | 735–2450 MPa | ||||||||||||||||||||||||||||||||||||||||

| CAS Number | 7440-03-1 | ||||||||||||||||||||||||||||||||||||||||

| History | |||||||||||||||||||||||||||||||||||||||||

| Naming | after Niobe in Greek mythology, daughter of Tantalus | ||||||||||||||||||||||||||||||||||||||||

| Discovery | Charles Hatchett (1801) | ||||||||||||||||||||||||||||||||||||||||

| First isolation | Christian Wilhelm Blomstrand (1864) | ||||||||||||||||||||||||||||||||||||||||

| Recognized as a distinct element by | Heinrich Rose (1844) | ||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||